An Add-in Tool for Accessible Modelling and Simulation of Impellers

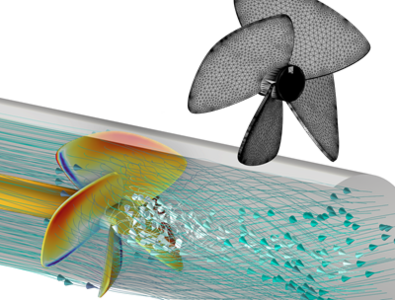

The use of impellers is extremely widespread across various industrial applications. Fluid motion, mixing processes, and propulsion are just a few of the fields in which impellers play a key technological role. In general, impellers enable energy transfer through the interaction between a solid structure and the fluid in which it is immersed. In the case of driven machines (such as fans or pumps), the interaction between the blades and the fluid allows mechanical energy to be transferred from the rotating shaft to the moving fluid. The type, number, and shape of the impeller blades determine their specific characteristics and functional behavior. For this reason, their characterization (in terms of flow rate and pressure as a function of the shaft’s rotational speed), as well as the accurate representation of both the intensity and direction of the components of the fluid flow field, are of primary importance in simulation models. However, accurately simulating the fluid dynamics induced by impeller rotation can be computationally demanding, especially when multiple impellers are integrated into a complex system. This work presents an application combining impeller characterization with a simplified numerical approach to simulate the swirl flow generated by the impeller in a more complex fluid dynamics model. The impeller geometry was obtained through 3D scanning and converted into a solid CAD model using dedicated software. A detailed COMSOL model was then developed using the Model Builder to obtain the relationship between rotational speed (RPM) and the resulting fluid flow rate. The rotation of the impeller was accounted for using the CFD Module, solving a Frozen Rotor study to capture centrifugal and Coriolis effects induced by rotation. This approach was preferred over the full Rotating Machinery interface due to its better computational efficiency in steady-state analyses. The study was carried out across a range of rotational speeds to derive a correlation between RPM and flow rate. However, applying this detailed model directly in larger systems with multiple impellers becomes computationally expensive. To address this, an Add-In was developed using the COMSOL Application Builder. This tool allows users to input key impeller characteristics—such as inner and outer radius, blade pitch angle, impeller position, rotational speed, and flow rate—and automatically generates the corresponding swirl flow equations within the Model Builder. This enables efficient integration of impeller-induced swirl effects into larger system-level simulations without the need to explicitly model the impeller geometry.