Efficient Thermo - Hydrodynamic Lubrication Modelling of Polymer Sliders accounting for Cavitation

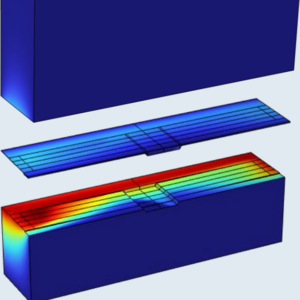

Introduction: Polymer materials are increasingly used in machine elements such as seals and plain bearings. In particular, PEEK has gained attention for use in wind turbine applications due to its strength and resistance to harsh operating conditions. However, its low thermal conductivity can lead to elevated contact temperatures in lubricated sliding contacts, which in turn affects lubricant viscosity, solid deformations, and ultimately the load-carrying capacity of the contact. This study investigates the rise in contact temperature in lubricated, textured PEEK sliders due to viscous dissipation, both numerically and experimentally. The bidirectional surface textures generate pressure buildup in converging regions and induce cavitation in diverging zones, making it essential to account for cavitation in hydrodynamic simulations. Modelling the coupled behaviour of cavitation and heat transfer can become computationally expensive, especially when heat conduction in the solids is considered. To address this, an efficient modelling strategy using COMSOL Multiphysics is proposed. Methodology: A coupled hydrodynamic lubrication and heat transfer model is developed. First, the full 3D model is constructed in SolidWorks. Hydrodynamic pressure is calculated using the 2D Reynolds equation with the Jakobsson-Floberg-Olsson (JFO) cavitation model and Fischer-Burmeister (FB) algorithm in an intermediate plane (effective plane) of the 3D film geometry. A constant reference temperature and viscosity are assumed initially. Variations of pressure in the thickness direction are negligible, so the 2D pressure results are extruded from the effective plane to the 3D geometry using COMSOL’s “General Extrusion” function. Local height is also calculated by measuring the z-coordinate of the top plane and extruding it to the entire 3D film domain using, again, the “General Extrusion” function. Then, using the extruded pressure and height fields, the 3D velocity field is reconstructed via the Poiseuille and Couette flow equations to feed into the heat transfer equations which are solved in both the fluid domain and the solid domain: the PEEK slider, and the counterface. The temperature field updates the fluid viscosity, and the hydrodynamic pressure distribution is recalculated iteratively until convergence is achieved (Fig. 1). For validation, experimental measurements of contact temperatures in textured PEEK face seals are carried out using infrared (IR) thermography. A sapphire disc – transparent to IR and with thermal conductivity similar to steel – is used as the counterface. The IR camera collects radiation from the oil film, PEEK surface, and sapphire disc. Using radiation heat transfer analysis, the actual contact temperatures are determined. Conclusions: This work presents an efficient approach to simulate thermal effects in lubricated sliding contacts (in this case PEEK) by combining 2D hydrodynamic modelling with 3D thermal simulations in COMSOL Multiphysics. By extruding 2D pressure and reconstructing the velocity fields rather than solving the full 3D fluid problem, computational costs are significantly reduced. The results offer insights into temperature development in polymer contacts, an area that remains underexplored, and can guide the thermal design of polymer-based tribological components.