Influence of Marangoni Effects in Gas Tungsten Arc Welding

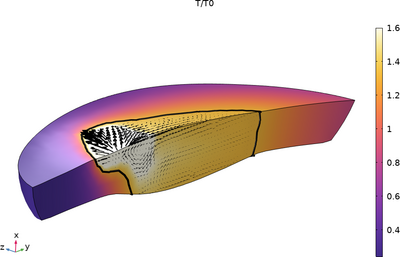

Arc welding is a widely used process in heavy industry for the assembly of metallic components. To ensure high-quality welds, it is essential to understand both the welding process and the complex interactions within the melt pool. Numerical simulation is employed as a predictive tool to complement real-time measurements, providing detailed insights into heat transfer and fluid flow. In this work, a 3D transient model is developed, solving the conservation equations for energy, momentum, and mass, while accounting for the deformation of the free surface using an ALE method and considering material addition during welding. Particular attention is given to Marangoni convection, with a focus on its sensitivity to sulfur concentration, which significantly influences surface tension gradients and melt pool dynamics. The simulation results show good agreement with literature and experimental data, highlighting the crucial role of sulfur-dependent Marangoni effects in shaping weld pool behavior and determining final weld quality.