Membrane modeling in carbon capture technology

Aqualung Carbon Capture [1] provides membrane modules that capture carbon, to aid in the decarbonization of heavy industry and transport. These modules filter CO2 from process gas streams with minimal additional pressure drops. We supported Aqualung by aiding in the improvement of a membrane module containing more than 2000 filtering fibers. Using the CFD module in COMSOL we calculated the efficiency of the module for different geometries.

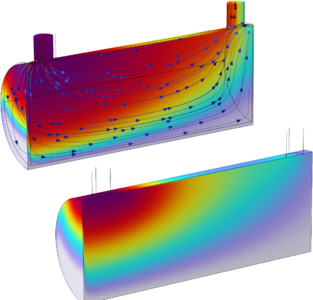

In Figure 1, the flow process and the modelling concept are shown. CO2 rich inflow enters the membrane module, passes through the membrane fibers where CO2 is absorbed, thus the outflow is deplete in CO2. In order to simulate CO2 filtering, two physical processes are of importance: (1) the pressure drop within the module and through the fibers, (2) the microscopic process of membrane filtering that depends on the concentration ratio of CO2 within the module vs within the fibers. Because the geometries can contain up to 2000 fibers, the simulation in COMSOL is simplified by splitting the system into two effective porous media: module and fibers.

For each medium, the interface ‘Free and porous media flow, Brinkman’ is used to calculate the velocity and pressure fields. The local concentrations in each medium are calculated using the interface ‘Transport of concentrated species’. The between the two interfaces is done using the Multiphysics ‘Reacting flow’ feature. The concentration and fluid flow are coupled using the Multiphysics coupling ‘Reacting flow’. Finally, the CO2 exchange between the two media: module and the fiber are coupled using a concentration and pressure dependent sink and source term respectively.

The result of the simulation, when applying all above mentioned boundary conditions, can be seen in Figure 2. The concentration of CO2 on the module side decreases across the module. At the same time, the CO2 emerges on the fiber side, locally increasing the concentration before flowing out of the module. This indicates that the module is working as intended and is extracting CO₂ from the feed flow.

Using CFD simulations, input parameters such as module geometry, fiber packing density, and process parameters can be quickly iterated to optimize the module. This means that the module can be tuned for specific industrial processes. In this way, a cost-benefit analysis can be performed, assessing CO2 capture purity and CO2 mass flow on the one hand, and the costs such as pumping power and size of the module on the other hand.