Modelling the dry conversion process with COMSOL Multiphysics®

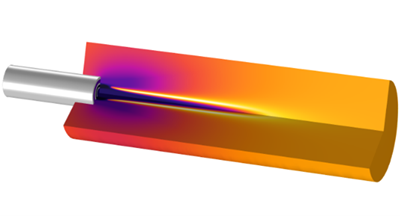

In the nuclear fuel industry, the dry conversion process is employed to transform crystalline UF6 to UO2 powder, in order to produce fuel pellets. The quality of the finished product highly depends on the process input parameters, and it is imperative to understand accurately the full processes to ensure a safe and reliable continuous fuel supply. These processes involve products that are difficult to handle and operate at high temperatures. Numerical simulations and modeling are powerful tools for assessing and optimizing them. The dry conversion process is a continuous chemical process composed of a reactor and a furnace in series. The reactor mixes pre-heated gaseous UF6 with steam to form UO2F2 powder in an exothermic reaction. The powder is then conveyed to the furnace, a heated tube within which the powder flows. Along the furnace, the UO2F2 powder transforms into UO2 powder in a series of exothermic and endothermic reactions with gases in counter flow. The entire process has been modelled using COMSOL Multiphysics®. In the reactor, the turbulent flow of gases and the thermochemistry of the flame are solved at steady state, allowing the estimation of the reaction location and the local temperature of the equipment. Then, the transport and growth of grains are modelled from nucleation until impact with walls of the reactor, providing the estimation of granulometry data of the UO2F2 powder. In the furnace, the turbulent flow of gases is solved to estimate the velocity and mixing level of gases. Then the thermochemistry along the furnace is modelled in a one-dimensional approach, to estimate the location of each reaction, the local temperature of the equipment, and the chemical composition of the powder produced. These models can be used to estimate the quality of the produced powder, while providing access to valuable unmeasurable data. Ultimately, sensitivity analyses can be performed to understand the combined effect of input parameters and help optimise the operating conditions.