Optimizing miniature phase change cells for in-process self-validating thermocouples

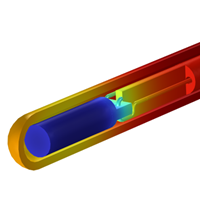

Thermocouples are widely used in industry for process temperature measurement. Calibration drift is a well-known problem which adversely affects process control, particularly in harsh environments (e.g. high temperature). To overcome this, a mechanism for self-calibration of thermocouples has been developed which makes use of a miniature phase change cell [1]. The phase change cell is located within the thermocouple assembly, near the measurement junction (i.e. the tip), so that when melting occurs, the temperature is held constant for a short time. Since the melting temperature is known, the thermocouple can be calibrated in situ. The cell is very small, containing less than 1 gram of phase change material, so great care is needed over the design to enable the detection of a robust, observable melting plateau. There are several subtleties associated with the practical realization of this technique, the most significant being the fact that the measurement junction is displaced from the phase change cell, not embedded within it, so that during melting its temperature is some weighted average of the melting temperature and the ambient temperature. This means that the indicated melting temperature depends on the ambient temperature, which is undesirable. It is of great interest to identify the part of the melting curve which is independent of the ambient temperature; this is most likely to be in the initial part of the melting process when the ambient temperature is close to the melting temperature. Because the true melting temperature is known in the simulation, modelling the system facilitates the development of practical, analytical approaches to finding this invariant part of the melting curve in the case of experimental data. The simulation is carried out using a three-dimensional time dependent heat transfer in fluids and solids model. Since the temperature range of interest is above 950 °C, heat transfer between all surfaces is modelled with surface-to-surface radiation. The melting is modelled using the phase change material interface. The simulation enables some general conclusions to be drawn, such as how to thermally decouple the phase change cell from the rest of the assembly to maximize melt duration and minimize other thermal perturbations, the effect of different environments (e.g. use in vacuum and in argon), the effect of ambient thermal parameters on the measured melting curve (i.e. ambient temperature and rate of temperature increase), and the effect of using phase change materials comprising of both pure metals and alloys (which have a wider melting temperature range). The NPL-designed self-validating thermocouple is in the process of being commercialized by CCPI Europe under the trade name INSEVA [2]. It is currently being trialed in high value heat treatment processes in the UK and Europe; the improvements in process temperature control by eliminating calibration drift mean better energy efficiency, better product consistency and yield, reduced pollution and reduced greenhouse gas emissions.