Coupled electrical and heat transfer model of hBN-encapsulated graphene

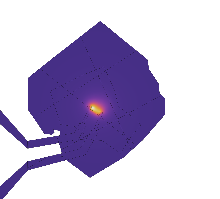

Calibration drift of temperature sensors is a well-known problem which adversely affects process control, particularly at high temperatures. Some new approaches are being developed [1,2], but degradation of resistive sensor elements is hard to prevent. To overcome this, graphene, which has desirable electrical properties such as a relatively high, tuneable resistance, has been encapsulated in hexagonal boron nitride (hBN) to protect it from oxidation. This involves nanofabrication of the hBN/graphene/hBN stack on a silicon/SiO2 wafer. Etched electrodes connect the graphene to external bonding pads to enable resistance measurement. Resistance measurement requires the application of a current, which causes Joule heating; this must be well understood. A coupled electrical and thermal model is implemented in COMSOL to quantify this Joule heating. The high aspect ratio (several mm across and tens of nm thick) causes some challenges with the modelling which can be overcome using domain partitioning and swept meshing. Transient coupled Electric Currents and Heat Transfer in Solids interfaces are used to apply a current across the electrodes (necessary to determine the resistance). The resulting Joule heating causes a temperature rise, which is the aspect of interest here due to its influence on the use of graphene as a temperature sensor. A swept mesh is used to handle the high aspect ratio geometries, with the use of a distribution node to ensure at least two elements along the thickness. This is complicated by the number of different crossovers between the layers. This can be resolved by partitioning the domains so that the geometry is more suitable for swept meshing. To manage the complexity, only two of the 10 electrodes are modelled. Because a convective heat transfer boundary condition is applied on all surfaces, the temperature rise depends on the convective heat transfer coefficient. As, in use, the device will be enclosed in a protective sheath, a coefficient of 5 m-2 K-1 is used [3], yielding a temperature rise of the entire assembly of approximately 4 mK (applied current 10 microAmps), with a localized peak in the temperature of the graphene. The underlying Si wafer acts as a heat sink. The model will be employed to examine both the stationary and transient ‘self-heating’ characteristics of the device, and the findings will be used to optimise its geometry. A key development making use of the graphene sensor element is a novel Johnson noise thermometer, which enables inherently driftless thermometry. More widely, the device offers the potential for more stable resistance thermometry above approximately 400 °C. The improvements in process temperature control by eliminating calibration drift mean better energy efficiency, better product consistency and yield, reduced pollution and reduced greenhouse gas emissions.