Impact of the Key Ageing Mechanisms in NMC Batteries and their Consequences in Degradation

Rapid increase in the global energy demand requires indispensable energy sources such as lithium-ion batteries. While batteries play a crucial role in meeting the global energy demand, during long operation Li-ion batteries go through undesirable effects causing the battery to age. Battery ageing is caused by side reactions and degradation processes at various places in the battery. The rate of degradation depends on cycling conditions, potential, local concentrations, and temperature. The growth of the parasitic solid-electrolyte-interface (SEI) layer and lithium plating (Li-P) on graphite anodes play a vital role in Li-ion battery degradation, causing reduced capacity, increased resistance, possible internal short circuits, resulting enhanced thermal runaway hazards. Detecting SEI growth and Li-P through non-invasive methods is crucial for monitoring and maintaining battery performance, safety and reliability.

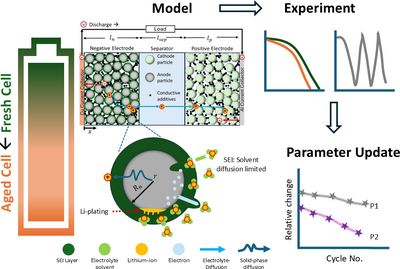

This study investigates the effects of SEI growth and Li-P on battery degradation through pseudo-two-dimensional model (P2D), which is based on the Doyle-Fuller-Newman (DFN) framework [Ref1]. The model accounts for the diffusion-limited SEI growth, resistance of the SEI layer, Li-P/stripping reactions, and more importantly the coupled interaction between these two major degradation mechanisms, which is often ignored in other studies. The coupling of Li-P and SEI formation was done by considering plated Li to gradually decay into inactive 'dead lithium', with the rate of this decay inversely proportional to SEI thickness [Ref2]. Simulations were performed using COMSOL Multiphysics® v6.3 and parts of Battery Design Module from the Application Libraries were used to create the model. For experimental validation, tests were conducted using NMC-622/graphite cylindrical-21700 prototype cells with 3.5 Ah nominal capacity from a commercial manufacturer at different cycling conditions. The test matrix was formulated with different charge-discharge and temperature (cycling only) conditions to identify Li-P and SEI formation. Electrochemical parameters were obtained from literature, experimental data, and a few were estimated using the Optimization Module. A summary of the workflow is shown in Figure 1.

Results indicate that at early stages of cycling, kinetics dominate the growth causing rapid SEI layer growth. As the SEI layer thickens, diffusion becomes rate-limiting, thus the growth slows down. The SEI layer becomes more stable over time , leading to slower capacity fade but a rise in potential drop in the anode due to SEI layer resistance. A parametric sweep of C-rates revealed that Li-P thickness increased more significantly at higher C-rates, consistent with trends reported in the literature. Discharge curves and state-of-health data (Figure-2) from the model and experiments (over several hundred equivalent cycles) showed good agreement, with a root-mean-square error (RMSE) of <11% for test condition: 0.3C/1C charge-discharge. Currently, due to unavailability of some parameters involved in the ageing mechanisms, validation for the ageing study will be done as soon as results become available. This degradation model provides valuable insights into the performance and ageing behavior of Li-ion batteries under varying operational conditions and thus can help define operational and design boundaries to reduce capacity loss and safety risks in Li-ion batteries.