Microwave plasma simulations for PECVD

Our customer LeydenJar Technologies creates the world’s most energy dense battery anodes, enabling Li-ion batteries that are powerful, small and fast charging. Prime examples of applications include electronic devices and e-mobility. The anodes are made of silicon, and are produced with plasma-enhanced chemical vapor deposition (PECVD), a process to obtain a controlled and clean deposition of a thin silicon film on a substrate. PECVD processes take place in a process chamber, which is under vacuum at pressures from roughly 0.1 Pa to 100 Pa. The substrate is inside the chamber and thin film deposition is achieved by means of generating a plasma that drives chemical reactions in which high purity materials are created. A homogenous deposition is desired, and simulations can aid in achieving the desired homogeneity. In collaboration with LeydenJar, we simulated a hydrogen plasma that is sustained by a microwave source.

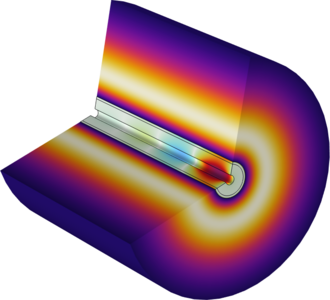

The modelled system consists of a quartz waveguide carrying a microwave. The microwaves propagate along the waveguide and are absorbed by the plasma formed in a cylindrical vacuum vessel around the waveguide. To model the plasma, a model was set up in COMSOL Multiphysics in which the Electromagnetic Waves, Frequency Domain and the Plasma interfaces were coupled. Since plasma simulations are computationally demanding, the choice was made to set up a two-component model in which the microwaves were modelled in a 2D-axisymmetric component, whilst the plasma was modelled as a 1D-axisymmetric radial component perpendicular to the waveguide. With this setup the plasma properties as a function of the distance to the waveguide could be obtained, which was our main interest.

For the hydrogen plasma several H-species were considered (a.o. H, H*, H**, H+, H2, H2+, H3+). The reaction rates were computed based on imported cross sections and rate coefficients. The propagation of the microwave through the waveguide depends on the conductivity of the plasma. At the same time, the microwave is the heating source of the electrons in the plasma, affecting the conductivity. By coupling the two components and exchanging the required quantities, a self-consistent model could be set up.

From this we could get insight into the plasma composition as a function of the distance to the waveguide, in particular the distribution of ions and other reactive species. Further quantities of interest were reaction rates, the microwave heat source, as well as the diffusivity of electrons and reactive species. Moreover, the model allows us to easily compute sensitivities to process parameters such as the input power or the size of the vacuum chamber.

At LeydenJar, our models made an impact in three different ways: • For insight: to understand the basic principles of the plasma source. • As inspiration: to help explain experimental observations. • Further development: to test ideas in simplified models. In conclusion, plasma simulations provide a powerful tool for accurately modelling complex plasma behaviour, enabling deeper insights into both fundamental physics and practical applications in semiconductor processing.