Multiphysics modelling and measurement correlation of a handheld induction heating device

This case study explains the work we undertook where we modelled an Induction heating system in COMSOL Multiphysics simulation software to correlate the simulation results with actual measurements.

The simulated results were cross checked with several different measurement scenarios, and they correlated quite well over an open loop 200 second measurement period.

Objective

The study’s main objective was to develop a model of an existing system and validate it with measurement data. This model will then help streamline next-generation product design by enabling quicker comparisons of design options, reducing reliance on costly and time-consuming iterative development.

System Description

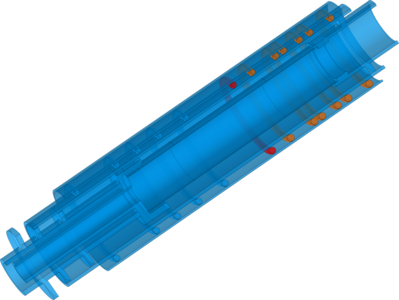

The system modelled is a handheld induction heating appliance. It runs off a DC battery which is the main power source. An inverter circuit converts the DC voltage into varying voltage to aid electromagnetic induction across the coil to a metal susceptor.

The metal susceptor is a single piece of ferromagnetic material which acts as a single turn secondary, and the induced eddy current is converted to heat thereby resulting in Induced heating of the susceptor.

<

Multiphysics Modelling

Modelling this system is complex and COMSOL Multiphysics simulator allows us to model all the parts in one tool – including circuit level, EM and Thermal simulation.

This Multiphysics measurement – simulation correlation activity can be divided into 3 distinct parts.

- Circuit level correlation, involving exact modelling of the inverter drive circuit.

- Electromagnetic energy transfer, which is a result of inductive coupling.

- Thermal energy generation on the secondary side on the susceptor.

<< Refer to Figure 2>>

Summary or results

The modelled system was compared with actual measurements and excellent correlation was seen. The simulated values quite closely match measured values over a very long period of time (200 seconds).

<< Refer to Figure 3>>

The temperature rise is very gentle in these tests, mainly because the power input to the coil is quite low. This is intentional, so that we don’t accidentally damage the test set-up due to overheating.

In reality, much more power is put into the primary and a software control loop is employed to maintain the temperature at a set point.

To show case that this model is fit for the real world, a very short simulation with real life power values was conducted and the results correlated well.

<