Simulation of heat and mass transfer in thermochemical hydrogen compressors

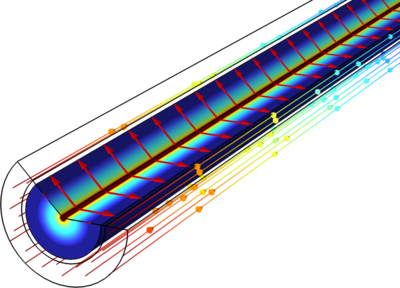

The reversible storage of hydrogen in metal hydrides represents an attractive technology for hydrogen-based energy systems. In addition to their application as pure hydrogen storage media, metal hydrides can also be used to develop thermochemical hydrogen compressors, which can be powered, for example, by waste heat and thus offer an energy-efficient alternative to mechanical compressors. However, a key challenge of this technology lies in the low thermal conductivity of many metal hydrides, which limits the dynamic charging and discharging speed. To specifically improve the kinetics, pelletized composite materials made of Hydralloy C5 and expanded natural graphite (ENG) were developed, which exhibit pronounced anisotropic thermal conductivity. The model, implemented in COMSOL Multiphysics 6.2, replicates the real geometry of a thermochemical compressor in which a central sintered tube is used to radially inject hydrogen into a surrounding composite bed made of Hydralloy-ENG. The storage material is surrounded by an annular cooling channel that is flowed through by a heat transfer fluid. The modeling accounts for anisotropic heat conduction in the storage material, convective heat transfer between the heat transfer medium and the reactor, hydrogen transport (Darcy flow) through the porous medium, as well as a nonlinear reaction kinetics based on an empirical description of the pressure-composition isotherms (PCI). Mass transport is modeled as a function of local porosity. The fully parameterized model enables a systematic investigation of the influence of ENG content, reactor diameter, heat transfer parameters of the fluid, as well as system pressure and temperature. All relevant operating phases – absorption, desorption, heating and cooling – are represented. The simulation results show that higher ENG contents and smaller reactor diameters lead to significantly shortened process times. The influence of system parameters is also evident. For instance, the absorption rate clearly depends on the hydrogen pressure in the sintered tube. The dependency on heat transfer to the heating and cooling medium is also clearly visible and indicates that liquid media with a minimum velocity of 0.5 m/s should be used for temperature control. Furthermore, the results show that a CFD modeling of the cooling medium is not necessary, as the heat transfer is described sufficiently accurately by a third-order boundary condition based on Nusselt-correlations. From the simulations, complete cycle times were determined, with a maximum total process duration of 10 minutes. The model was subsequently used to design a thermochemical compressor containing 20 kg of storage material, which consists of four individual reactors. The simulation results form the basis for the ongoing construction of the reactor. Thermal outputs were derived and used for the design of the heating and cooling system. The next step involves experimental validation of the simulation model under real operating conditions. This will turn the model into a powerful tool for the development, scaling, and optimization of future metal hydride-based thermochemical hydrogen compressors.